Just as you’ve started exploring die cutting machines, the market has exploded with innovative options that’ll transform your crafting projects. You’ll find everything from compact manual devices to robust electric machines, each offering unique capabilities for different materials and project scales. Whether you’re a hobbyist or professional, understanding the distinctive features of these top five machines will help you make the right investment for your specific needs.

Electric Die Cut Machine for Art & Craft (9 inch)

Crafters seeking an electric die-cutting solution will find the 9-inch model’s extensive accessory kit particularly appealing. You’ll receive plates, papers, dies, and embossing materials right out of the box. The machine’s ABS shell and metal gears guarantee durability while maintaining a compact footprint.

This electric model stands out for its user-friendly operation, especially if you have arthritis or other physical limitations. It handles materials up to 9 inches wide and excels at A4-sized projects. While some users report challenges with magnetic sheets and initial learning curves, most praise its value compared to pricier alternatives. The responsive customer service quickly addresses any plate replacement needs.

Best For: Craft enthusiasts who need an electric die-cutting machine for A4-sized projects, particularly those with physical limitations like arthritis or those seeking a comprehensive starter kit.

Pros:

- Comes with extensive accessory kit including plates, papers, dies, and embossing materials

- Electric operation makes it easier to use than manual machines, especially for those with physical limitations

- Good value for money compared to more expensive brands with similar features

Cons:

- Some users report difficulties cutting through magnetic sheets

- Initial learning curve can be challenging for beginners

- Occasional inconsistent performance and slower operation than expected

Sizzix 660200 Big Shot Manual Die, 6 Inches

The Sizzix 660200 Big Shot Manual Die offers three essential qualities that make it perfect for small-scale crafting operations: versatility, precision, and reliability.

You’ll appreciate its compatibility with various materials, from paper to balsa wood, while its 6-inch opening accommodates most standard dies. The machine comes equipped with everything you’ll need: standard cutting pads, a multipurpose platform, and a thin die adapter. While it’s manual rather than electric, you’ll find this feature advantageous for controlled cutting precision.

With a 4.6-star rating from over 5,900 users, this 7.5-pound workhorse proves its worth in crafting applications where consistency matters more than automation.

Best For: Hobbyist crafters and small business owners who need reliable manual die cutting for paper crafts, card making, and scrapbooking projects requiring precise, consistent results.

Pros:

- Versatile material compatibility (paper, fabric, felt, cork, thin wood)

- Complete starter kit includes all necessary accessories

- Manual operation allows for better control and precision

Cons:

- Limited to 6-inch width materials

- Cutting plates may need periodic replacement

- Not compatible with Plus and Pro dies from Sizzix

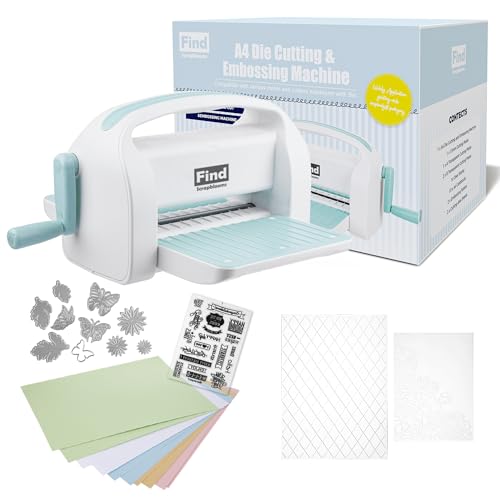

9 inch Die Cutting Machine, A4 Embossing Machine for Card Making

Designed for both novice and experienced crafters, the 9-inch die cutting machine offers versatile A4 paper capabilities while maintaining portability. You’ll find a complete starter kit including colorful cardstock, die cuts, clear stamps, and embossing folders.

Built with high-quality ABS and carbon steel, this machine withstands drops and frequent use. You’ll need to follow specific layering instructions: use the 13mm plate plus two 3mm plates for embossing, or the 13mm plate with a 2mm plate for die cutting. While some users report unclear instructions and occasional stuck dies, the machine’s larger cutting space and smooth operation make it a reliable choice for card making projects.

Best For: Hobbyists and card makers seeking a versatile, portable die cutting machine that can handle A4-sized projects while maintaining an accessible price point.

Pros:

- Complete starter kit includes essential materials like cardstock, die cuts, and embossing folders

- Durable construction with high-quality ABS and carbon steel materials

- Large 9-inch opening accommodates A4 paper and various project sizes

Cons:

- Instructions can be unclear and challenging for beginners

- Small dies may get stuck during operation

- Plates may show wear over time and require replacement

Sizzix Sidekick Portable Manual Die Cutting Machine (661770)

Portable and precise, the Sizzix Sidekick 661770 excels at small-scale die cutting projects while maintaining professional-grade results. You’ll find this 0.7kg machine perfect for crafting on the go, with its compact 7 3/4 x 4 3/4 x 3 1/2-inch frame.

The Sidekick handles lightweight cardstock and paper with ease, accommodating dies up to 2.5 inches wide. The starter kit equips you with Framelits dies, Thinlits dies, embossing folders, and stamps. Vacuum suction cups keep it stable on smooth surfaces, though you might need multiple passes for thicker materials. While it won’t replace larger machines, it’s ideal for quick projects like word dies and butterflies.

Best For: Beginner crafters and hobbyists who need a portable die-cutting solution for small projects like cards, word dies, and decorative elements.

Pros:

- Highly portable and lightweight at 0.7kg with compact dimensions

- Comprehensive starter kit includes dies, embossing folders, and stamps

- Vacuum suction cups provide stability on smooth surfaces

Cons:

- Limited to small dies up to 2.5 inches wide

- May require multiple passes for thicker materials

- Suction cups may not perform consistently on all surfaces

VEVOR Leather Cutting and Embossing Machine

Professional craftspeople seeking a robust die cutting solution will find the VEVOR Leather Cutting and Embossing Machine delivers exceptional value. With a 1.5-ton load capacity and 26 x 12 mm embossing plate, it’s built for serious work across multiple materials including leather, PVC, and rubber sheets.

You’ll appreciate the machine’s durability, featuring high-quality steel construction with black oxide coating and manganese steel base plate. The 0.47-inch adjustable stroke handles various material thicknesses, while limiting screws prevent rebound during operation. Though some users report initial setup challenges, the machine’s performance with leather die cutting and versatility across crafting projects makes it a worthwhile investment.

Best For: Professional leather crafters and serious hobbyists who need a heavy-duty cutting and embossing machine capable of handling diverse materials with precision.

Pros:

- Robust 1.5-ton load capacity with high-quality steel construction for long-lasting durability

- Versatile application across multiple materials including leather, PVC, and rubber sheets

- Stable operation with heavy-duty base plate and anti-rebound limiting screws

Cons:

- Setup and assembly can be challenging with some reports of missing or incorrectly assembled parts

- Initial calibration process may require time and additional adjustments

- Limited assembly instructions and tools included in the package

Factors to Consider When Choosing an Industrial Die Cutting Machine

When you’re selecting an industrial die cutting machine for your operations, you’ll need to evaluate several critical factors that directly impact performance and suitability. You should assess the machine’s material compatibility range, power requirements, and maximum cutting width to guarantee it meets your production needs. The machine’s build quality, durability, and available operating speeds will also determine its long-term value and production efficiency.

Material Compatibility Range

Material compatibility stands as a critical factor when selecting an industrial die cutting machine for your operations. You’ll need to verify your machine can handle diverse materials like card stock, fabric, leather, PVC, and non-sticky materials to maximize project versatility.

Check the machine’s load capacity specifications, as this determines its ability to cut through thicker or denser materials effectively. You’ll want to confirm the maximum material width limits and compatible die types, including standard dies, thin dies, and embossing plates. Each machine has specific compatibility restrictions that could affect your production capabilities.

Pay close attention to thickness handling specifications, as they directly impact cutting quality across different materials. Your chosen machine should maintain consistent performance regardless of the material’s density or composition.

Power Source Requirements

Beyond material compatibility, understanding power source requirements plays a fundamental role in die cutting machine selection. You’ll need to verify that your facility’s power infrastructure can support your chosen machine’s voltage requirements and provide stable power delivery for peak performance.

Manual die cutting machines offer flexibility since they don’t require electrical power, making them ideal for locations without reliable access to electricity. However, if you’re considering an electric model, you’ll need to check its power specifications carefully. Industrial machines with higher cutting capabilities typically consume more energy, which can affect your operational costs. It’s also essential to confirm whether your chosen machine supports different power settings or can work with transformers to adapt to your region’s electrical standards. This guarantees smooth operation and prevents potential damage to the equipment.

Cutting Width Capacity

The cutting width capacity of your die cutting machine serves as an essential determinant of production capabilities and workflow efficiency. You’ll find industrial machines offering widths from 6 inches to over 30 inches, letting you match the capacity to your specific needs.

When selecting cutting width, you’ll need to take into account your typical project requirements. If you’re working with large sheets of material or handling bulk production, a wider capacity will help you avoid multiple passes and speed up your workflow. For card making, you might need less width than for packaging or textile applications.

Don’t forget to factor in your material type. Heavier or thicker materials may require specific width capabilities to guarantee clean, precise cuts. Choose a width that aligns with both your current needs and potential future projects.

Durability and Build Quality

When investing in an industrial die cutting machine, durability and build quality should be your top priorities since they directly impact long-term performance and reliability.

Look for machines constructed with high-strength materials like steel or reinforced plastics that can withstand continuous use. You’ll want features such as black oxide coating or rust-resistant finishes to protect your investment, especially in demanding industrial environments. A heavy-duty base plate is essential as it provides stability and minimizes vibration during operation.

Check the machine’s load capacity carefully – it’s a key indicator of its structural integrity and ability to handle tough materials. Don’t forget to evaluate maintenance accessibility and user-friendly features like adjustable pressure strokes. These elements will guarantee your die cutting machine maintains peak performance throughout its service life.

Operating Speed Options

Operating speed capabilities represent an essential factor in selecting your industrial die cutting machine, directly impacting production throughput and overall efficiency. You’ll find machines that can achieve speeds of over 60 strokes per minute, often equipped with servo motors or pneumatic systems to maintain precision at higher speeds.

When evaluating speed options, you’ll need to match the machine’s capabilities with your material requirements. While faster speeds boost productivity, they might compromise cut quality on thicker or tougher materials. Look for machines with adjustable speed settings, as they’ll give you the flexibility to optimize performance for different projects.

Remember that consistently running at high speeds can accelerate component wear. You’ll want to factor in maintenance costs and the availability of replacement parts when choosing a machine that meets your speed requirements.

Safety Features Assessment

Beyond operational speed, safety features must be your top priority when selecting an industrial die cutting machine. You’ll want to verify that the machine has reliable emergency stop buttons and automatic shut-off mechanisms that activate instantly when needed. Look for adjustable pressure settings that prevent material damage and reduce injury risks.

Make certain the machine includes proper safety guards and enclosures around moving parts to protect operators during use. Check that all safety instructions and warning labels are clearly visible and easily accessible. The machine’s design should also incorporate a stable base with balanced weight distribution to eliminate tipping hazards during operation. These safety elements aren’t just add-ons – they’re essential features that protect your workers and guarantee compliance with industry safety standards.

Price Versus Performance

Making a smart investment in an industrial die cutting machine requires careful analysis of both price and performance factors. While you’ll find machines ranging from $1,000 to $20,000, focusing solely on price can be misleading. You need to evaluate cutting speed, precision, and material versatility to guarantee operational efficiency.

Consider machines with superior durability, even if they cost more upfront. They’ll often save you money through reduced maintenance and longer service life. Don’t forget to check the availability and cost of compatible dies and accessories, as these affect your long-term expenses. Additionally, examine warranty coverage and customer support quality – these features can greatly influence your total ownership costs. By weighing these elements against the initial investment, you’ll make a more informed decision that balances price with performance.